M-series displacement sensor accessories/accessories

TEC displacement sensors, as high-precision and high-stability measurement devices, are widely used in various industries such as metallurgy, wind power, engineering machinery, rubber machinery, port machinery, mining machinery, and industrial automation. To ensure the stable operation and accurate measurement of these sensors, the accompanying accessories and components are equally crucial. Below is a detailed introduction to the commonly used accessories and components for TEC displacement sensors.

1. Magnetic Rings and Magnetic Ring Mounts

Magnetic rings are one of the core components of TEC magnetostrictive displacement sensors, and their material and precision directly impact the accuracy of measurement results. Magnetic rings are attached to magnetic ring mounts, which are then installed on the measuring rod or piston rod. The design of magnetic ring mounts must consider stability and ease of installation to ensure that the magnetic rings do not shift or fall off during the measurement process.

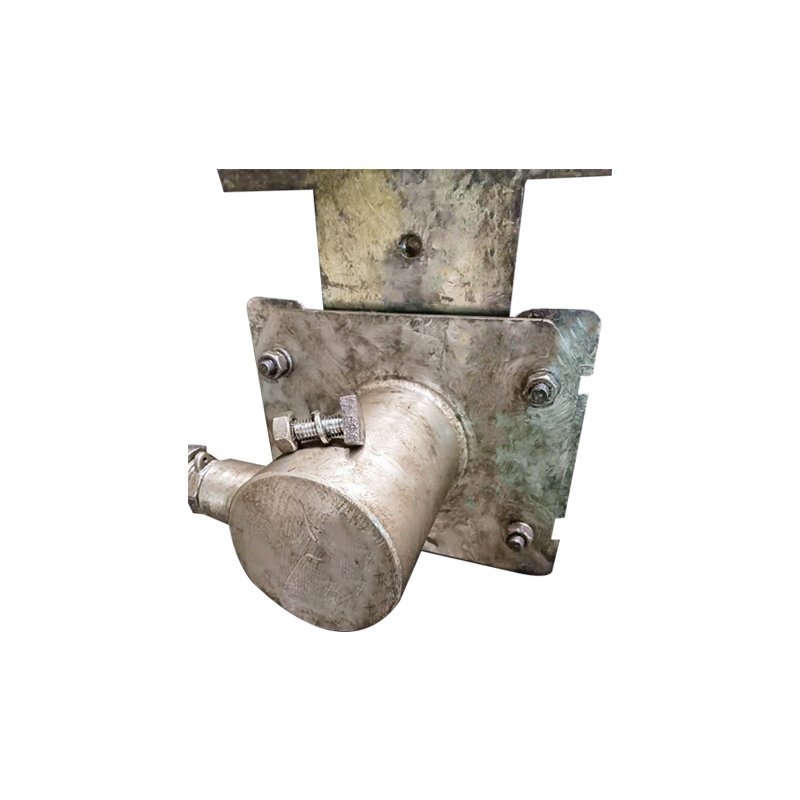

2. Sensor Mounts

Sensor mounts are used to fix TEC displacement sensors in predetermined positions, ensuring stability and accuracy during measurement. The design of these mounts varies based on the sensor model and installation environment, supporting various installation methods such as screw, threaded, and flange connections to meet different scenarios.

3. Cables and Connectors

Cables serve as the signal transmission medium between sensors and control systems, and their quality and length directly affect the stability and reliability of signal transmission. TEC displacement sensors are typically equipped with high-quality, anti-interference cables and dedicated connectors to ensure accurate and secure signal transmission.

4. Fixing Plates and Measuring Rods

Fixing plates are used to secure the sensor assembly at the end of the measuring rod, ensuring stability and accuracy during measurement. Measuring rods, on the other hand, are the crucial components connecting the sensor and magnetic rings. Their material and precision are equally important. Measuring rods are customized based on specific measurement requirements to ensure accurate and reliable measurement results.

5. Calibration Tools and Software

Although TEC displacement sensors are known for their high stability and low maintenance requirements, they still need to be calibrated upon initial installation or after prolonged use. To facilitate this process, manufacturers like Zheda Jingyi provide professional calibration tools and software, enabling users to easily complete calibration work and ensure the accuracy and consistency of measurement results.

6. Protective Covers and Dust Caps

In harsh working environments, protective covers and dust caps effectively shield TEC displacement sensors from dust, moisture, and other external factors, prolonging their service life. These accessories are typically made of high-strength, corrosion-resistant materials, providing excellent protection.